Saurer Allma CC2/CC3 Spindle Motors: A Closer Look

Saurer Allma CC2/CC3 Spindle Motors: A Closer Look

The CC2 and CC3 spindle motors have left a significant mark in the world of yarn twisting and cabling. In this article, we delve into the features, advantages, and competitors of these spindle motors.

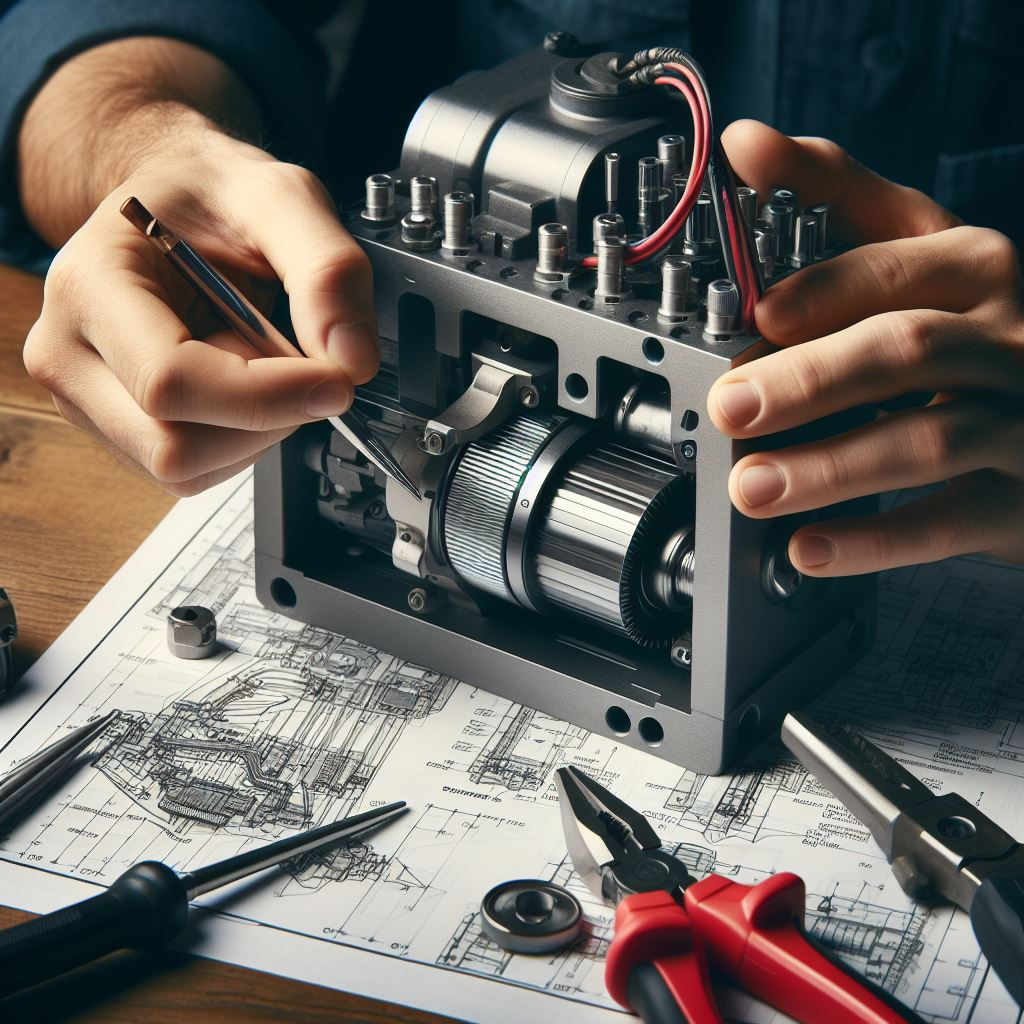

Saurer Allma CC2 Spindle Motor

Overview

The CC2 spindle motor is a workhorse in the textile industry. Here are some key features:

Proven Performance: The CC2 has been in the market for over 25 years, demonstrating its reliability and robustness.

Quality Twisted Yarn: The latest generation, the Series 8, sets new standards for twisted yarn quality. It ensures excellent cross-wound delivery packages.

Energy Efficiency: With low energy consumption, the CC2 contributes to cost savings.

Ease of Maintenance: Designed for easy handling and cleaning, it minimizes downtime.

Competitors

While the CC2 stands tall, it faces competition from other spindle motors:

TechnoCorder TC2: Saurer’s TechnoCorder TC2 offers versatility and tailored yarn processing1. It’s a high-performance machine for twisting single and multiple yarns across various counts.

Volkmann CT and FT: Volkmann’s CT and FT models cater to carpet yarns, combining efficiency and reliability.

Oerlikon Saurer GT: The GT ring twisting system by Oerlikon Saurer is another contender in the market.

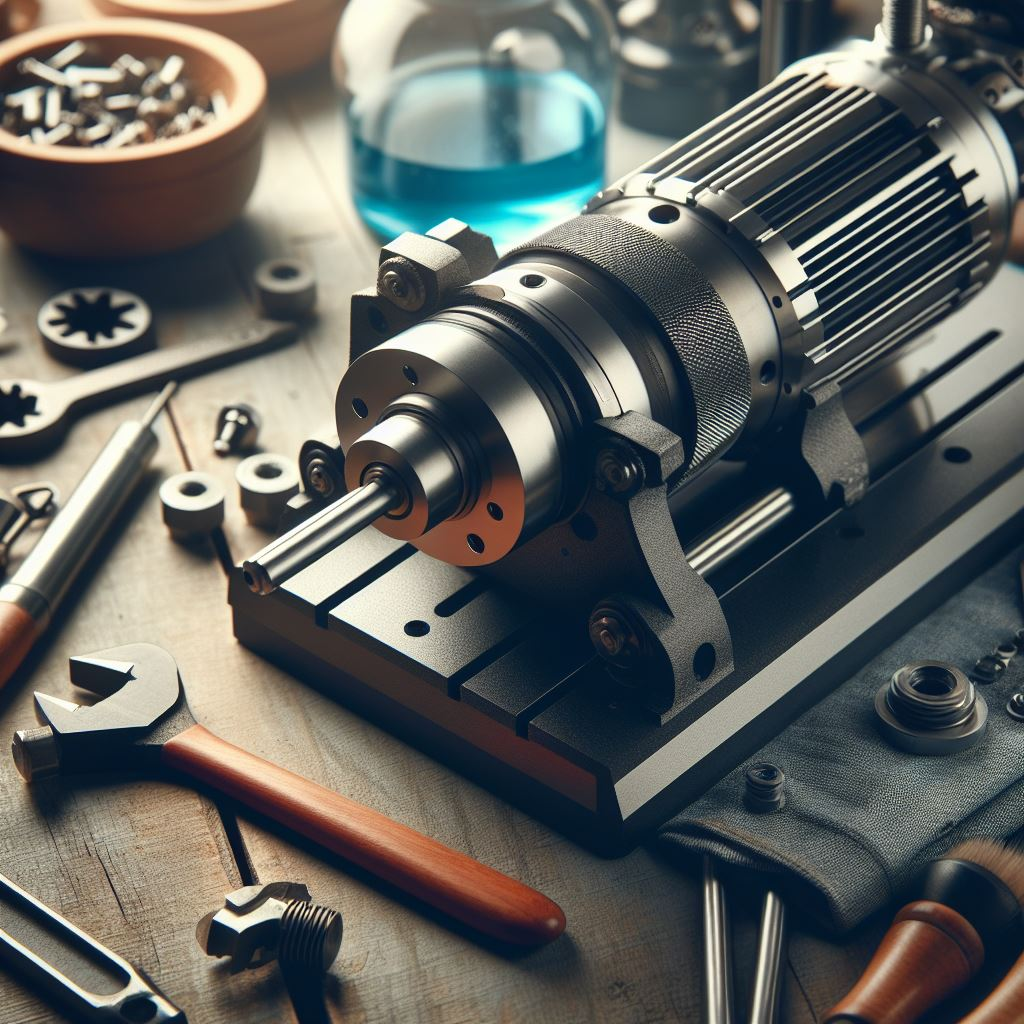

Saurer Allma CC3 Spindle Motor

Overview

The CC3 spindle motor builds upon the success of its predecessor. Here’s what you need to know:

Advanced Technology: The CC3 incorporates cutting-edge innovations for improved performance.

Precision Twisting: It ensures precise yarn twisting, meeting the highest quality standards.

Space-Saving Design: The CC3 optimizes floor space, making it ideal for modern textile mills.

Competitors

The CC3 faces competition from:

Volkmann HS: Volkmann’s HS glass filament yarn spindle motor offers reliability and consistent results.

Allma Systems TC2: While not a direct competitor, the TC2 complements the CC3 by addressing different yarn processing needs.

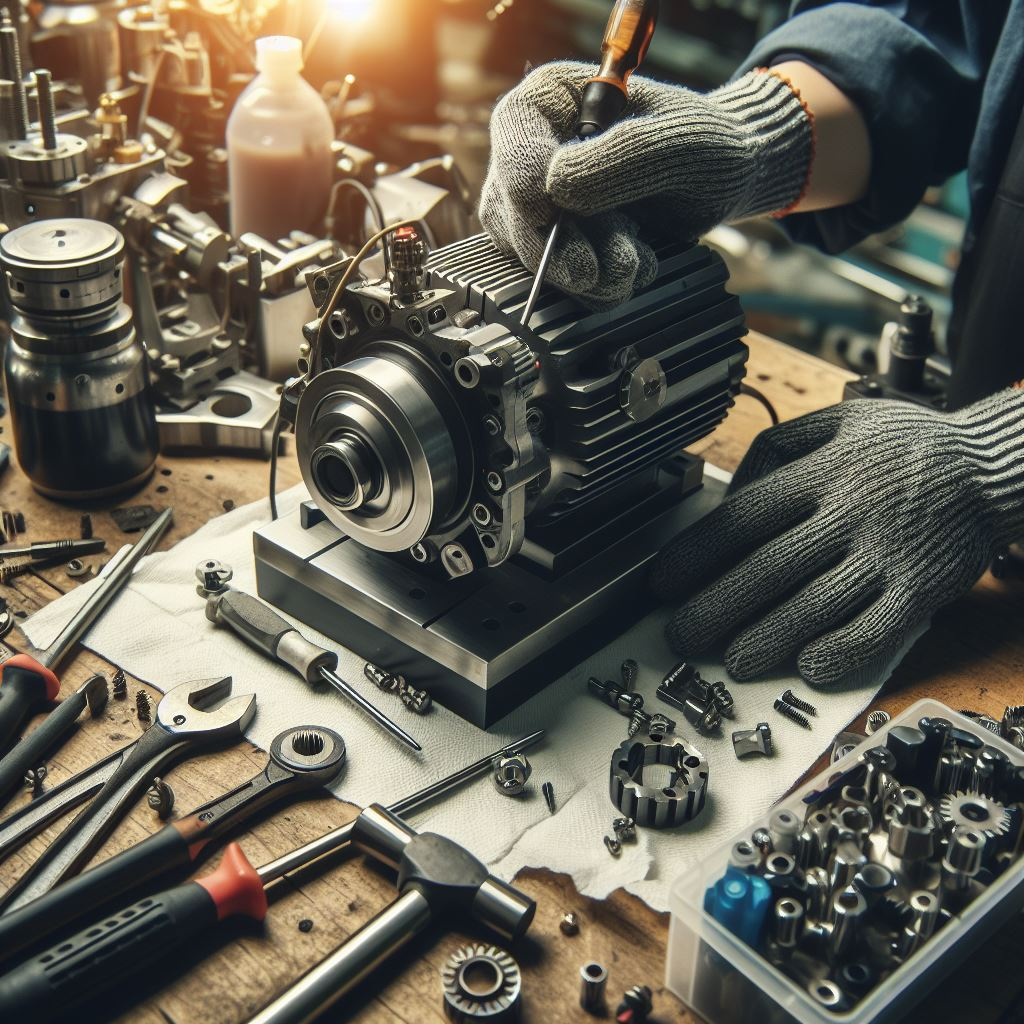

Conclusion

Saurer Allma’s CC2 and CC3 spindle motors continue to shape the textile industry. Whether it’s about quality, efficiency, or space utilization, these motors remain indispensable. As technology evolves, we eagerly await the next chapter in their legacy.

Remember, behind every yarn twist lies the ingenuity of these remarkable machines.